The Importance of Safe Dust Collection in Battery Manufacturing

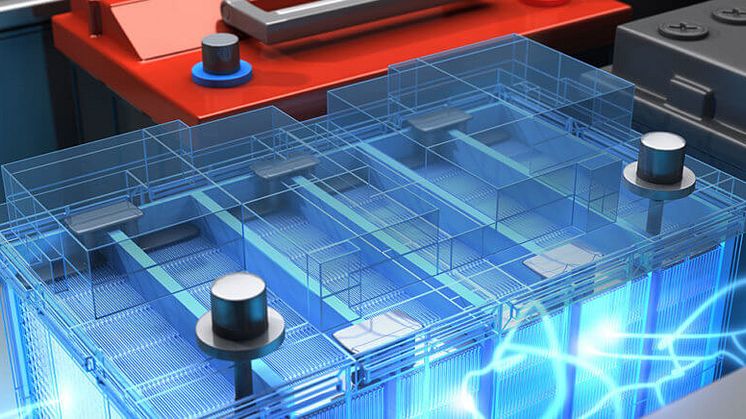

The processes involved in manufacturing batteries can release particles into the air – lead dust, nickel, cobalt, aluminum and other materials that are combustible and/or toxic. Though these dusts and fumes are generally emitted near process equipment, once in the air they disperse and eventually settle on equipment, floors, walls and other surfaces.