Blog post -

3 Important Tips for Controlling Dangerous Dusts in Manufacturing and Processing Facilities

Manufacturing and processing facilities across many different industries have one common challenge – containing the dangerous dusts. Operations that produce dust threaten the safety of workers, the facility and even customers who might encounter dust particles in the end product. While every type of dust has its own specific requirements and regulations, there are 3 important things that facility operators can do to effectively control the nuisance and hazardous dusts they produce.

1. KNOW YOUR DUST

We’ve said it before but it bears repeating, having a strong and thorough knowledge of the dust(s) produced by your operations is critical to ensuring that you are operating safely. Many dusts are explosive, flammable or can cause health issues if not maintained properly.

The best way to know your dust is to have it analyzed. The burden of proof is on manufacturers to demonstrate that their dust is not combustible, so it is important to have process dust tested by a valid third-party testing lab and to keep records on file proving that it is not combustible. If your dust is determined to be combustible, consult with an expert about adding explosion vents, baffles and other protective equipment to your dust collection system as needed to mitigate an explosion.

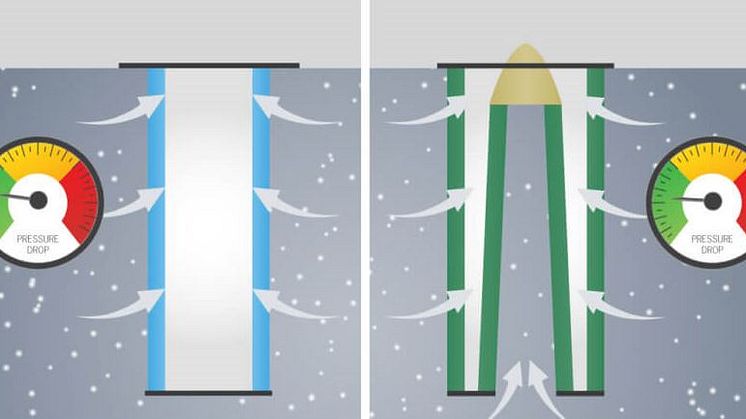

It also is important to analyze other dust characteristics to determine the best dust collection system and filters for your operation. Key dust properties include particle size, shape, gravity, moisture level and abrasiveness. Dust collection equipment suppliers often can conduct dust sample bench testing and work with you to specify the best system for your application.

2. KNOW THE REGULATING BODIES

There are four primary regulating bodies with rules in place to help maintain safety standards surrounding dust.

Occupational Safety and Health Administration (OSHA)

OSHA is the leading governing body for workplace safety, so there is no surprise that their regulations cover dust and dust exposure to facility workers. Their General Duties Clause mandates that employers offer employees a safe workplace free from recognized hazards that can cause death or serious physical harm. In addition, OSHA regulates permissible exposure limits (PELs) for many types of hazardous contaminants like dust and fumes.

National Fire Protection Association (NFPA)

The NFPA is an international organization dedicated to preventing death and property damage from fire, electrical and other related hazards. NFPA 652 is a standard related directly to the fundamentals of combustible dust. One of the key requirements of NFPA 652 is completing a dust hazard analysis. Completing this analysis helps you better understand your dust and ensures that your dust collection system is outfitted with all necessary safety controls to prevent or mitigate deflagration.

Food and Drug Administration (FDA)

Many dusts produced in both food and pharmaceutical manufacturing are not only potentially explosive but can also cross-contaminate other items being produced in the same facility if they are not adequately contained.

The FDA’s Food Safety Modernization Act requires food processing facilities to implement measures to ensure that contamination hazards will be minimized or prevented. These include controls for processes, food allergens, sanitation, and supply chain, as well as having a recall plan.

Environmental Protection Agency (EPA)

The EPA protects the environment and, in relation to dust collection, regulates exhaust systems that vent outdoors. Mandates like National Emission Standards for Hazardous Air Pollutants (NESHAP) Rule 6X, ensure that hazardous air pollutants produced by metal fabrication industries, known as metal finishing hazardous air pollutants (MFHAPs), are fully filtered or contained before emissions are released outdoors.

3. FIND A PARTNER

There are a lot of regulations and information to keep in mind when it comes to dangerous dust and dust safety. That’s why it’s important to find a partner with the right expert knowledge to make sure your facility controls the dangerous dust produced during operations. Camfil APC partners with manufacturers to learn about their process dusts, recommend the best filters and design the right dust collection system to ensure that your employees are safe and your facility is compliant with all regulations.

To learn more about keeping dangerous dusts under control in your facility, listen to the OH&S SafetyPod featuring John Ladwig, Systems Market Manager for Camfil APC.