Blog post -

How to Determine the Right Filter Media for Your Application

It’s easy to understand why dust collectors are necessary for manufacturing and processing facilities that produce dust and fumes. However, when it comes to dust collector filters, many believe that they can order the lowest cost filter cartridges that fit their dust collectors. Unfortunately, by using dust collector filters that are not designed to handle the specific dusts you produce, you can be wasting money and putting your workers and facility at risk.

There are two basic factors to consider when specifying dust collector filter cartridges: media type and fabrication technology. Filter media is the material used in the cartridge to capture dust particles. Generally, each cartridge contains hundreds of square feet of media folded up like an accordion so it fits in a small space. The base media is generally a nonwoven fabric, but that fabric is often coated with chemicals to provide specific performance properties such as anti-stick, conduction, static dissipation and flame retardance.

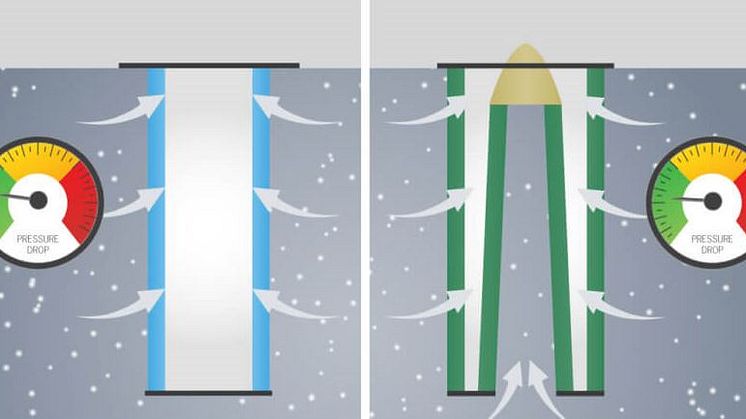

Fabrication technology is the way in which the media is folded into the cartridge. For example, Camfil’s HemiPleat® folding technique makes sure that pleats are uniform across the entire media and applies a plastic bead between the folds. This holds open the pleats so they don’t get pressed together, and more fabric is exposed to the airstream and able to capture dust particles. Together, the filter’s media and technology can make a huge difference in maintaining airflow, efficiency and a low pressure drop.

To help you better understand which type of filter is right for your application, we’ve outlined a few of the most common types of dust and the best type of filter for those applications.

HAZARDOUS AND TOXIC DUST

Hazardous and toxic dusts like hex chrome, silica or active pharmaceutical ingredients can cause lung disease in workers. They can also be combustible and an explosion hazard. These dusts need to be promptly captured and properly contained. The EPA and OSHA might require a high-efficiency filter that is chemically treated with an additional layer of nanofibers or PTFE. The added PTFE membrane helps maintain airflow with low pressure drop, and offers superior dust cake release during pulse cleaning.

We recommend: HemiPleat® PTFE or Dura-Pleat® PTFE filters

HYGROSCOPIC AND STICKY DUST

Hygroscopic dusts are most commonly found in the food processing industry, particularly where ingredients contain fats and oils. Dusts that are hygroscopic absorb moisture from the air, and once they land, they become sticky. This is one of the main reasons that standard dust collector filters fail in these applications. To prevent filters from becoming overloaded with sticky dusts, select a filter with media that has been treated with an oleophobic coating. This coating enables the filters to release buildup easily during pulse cleaning.

We recommend: Dura-Pleat Hydro Oleophobic or Standard Dura-Pleat filters

FIBROUS DUST

Fibrous dust is most commonly the result of processing wood, paper, sand or cellulosic food ingredients. This type of dust is challenging because the dust’s surface fibers can easily attach to the filter media, restricting airflow and causing holes and tears. Filters made out of spunbond media are recommended for these applications. Spunbond is a nonwoven fabric made in one continuous process. The fibers are spun then dispersed into a web, creating a stronger material. For extremely difficult cases, the spunbond media can be treated with an anti-stick coating like PTFE to help more dust be released during pulse cleaning.

We recommend: Standard Dura-Pleat or Dura-Pleat PTFE filters

FLAMMABLE DUST

During hot work and metalworking applications like plasma cutting, laser cutting, welding or grinding, there is an increased risk for fire or explosion. If your operations involve any of these tasks, your dust should be tested for flammability and burnability to determine if flame-retardant filter media is necessary. Dust testing will also determine the ignition energy so you know if you require media coated with a conductive aluminized finish. Dust collectors used for these applications should also be equipped with NFPA-approved explosion protection systems like explosion vents, isolation valves and safety monitoring filters.

We recommend: HemiPleat FR or HemiPleat eXtreme FR filters

STATICALLY CHARGED DUST

Some dusts, like dry food dust, fumed silica dust, PVC dust or toner dust, create static electricity while being collected and moved through the dust collector. These dusts are high risk for deflagration if the electrical charge is not dissipated. Two good filter media choices to conduct the charge and dissipate it safely are:

- Cellulose media impregnated with a carbon coating

- Synthetic filter media coated with aluminized material

Like dust collectors that handle flammable dust, dust collectors used for these applications should also be equipped with NFPA-approved explosion protection systems.

We recommend: HemiPleat Carbon or Dura-Pleat Aluminized filters

DUST CONTAINING ALLERGENS OR IRRITANTS

Food processing plants must take extra care to ensure that the foods they are producing do not become contaminated by food dusts from neighboring production lines. Any unintentional food dust that comes into contact with the food produced could pose a serious risk to consumers with food allergies or sensitivities, particularly if the ingredient is not listed on the packaging. For these applications, the EPA may require high-efficiency media with a nanofiber coating. The thin layer of nanofibers gives the base material larger pores to provide superior dust release and efficiency without increasing pressure drop.

We recommend: HemiPleat eXtreme filters

NUISANCE DUST

Not all dusts are harmful to humans if the level of concentration in the air is kept below specific levels. These levels are clearly outlined and regulated by organizations like OSHA. Dusts that are not harmful are known as nuisance dusts. These dusts are often generated by activities such as grinding, sanding and polishing. For nuisance dusts, it is generally safe to use a standard filter media made from nonwoven or cellulosic blend treated with a material to provide moisture resistance.We recommend: HemiPleat Green filters

Camfil APC filter cartridges are designed to capture the maximum amount of dust and air pollutants and then release them thoroughly when pulse cleaned. Using the correct filter media creates a safer, cleaner work environment with less dust collector maintenance. For help determining the type of dust generated by your operations, or to learn more about which filter is right for you, contact a Camfil dust collection expert today.