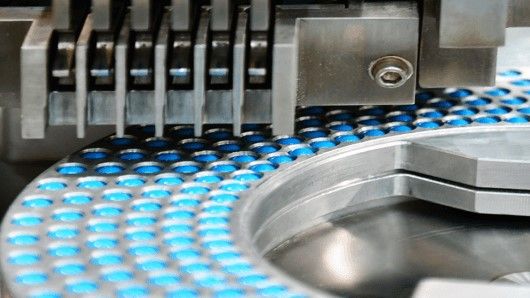

Pharmaceutical Dust Collection Update by Camfil APC Addresses Critical Containment Strategies for Oral Solid Dose Manufacturing

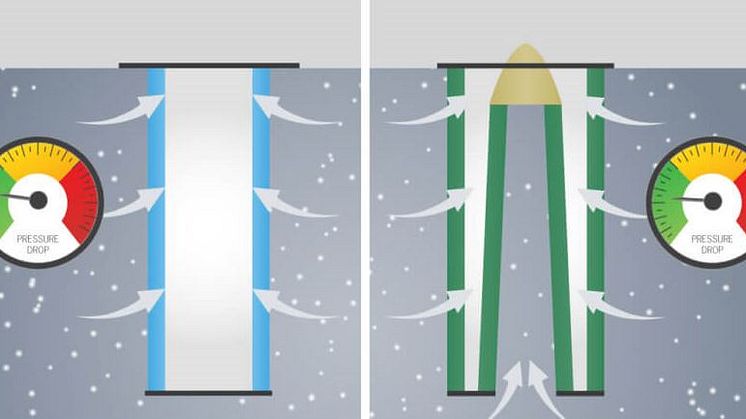

Jonesboro, Arkansas – June 13, 2025 – Camfil APC, a leading manufacturer of industrial dust collection systems, today announced a major pharmaceutical dust collection update addressing critical containment challenges in oral solid dose (OSD) manufacturing. The comprehensive technical resource provides pharmaceutical industry professionals with essential strategies for managing potent compound dust